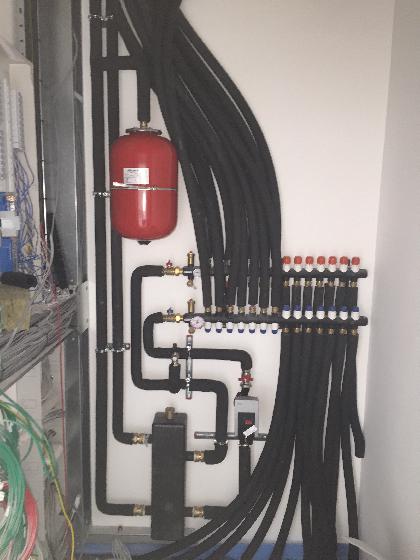

The image above is an example of one of the many poor heat pump installations we come across. This is giving heat pumps an unjust bad name. We are putting right the errors of other installers more frequently than installing our own heat pumps, possibly because our installs are at the higher price point. We are happy to correct others work as much as we can but I am writing to save others from making the mistake of falling for a price that is too good to be true. I would also like to inform you of why replacing a gas boiler with a heat pump is a wise thing to do for your pocket, future generations and the planet.

The first tell tale sign you have had a cheap and bad job done will probably be a poor finish, that’s assuming you even call the job finished before the cowboy installer. The pipework may not look aesthetically pleasing, cable management an afterthought. Holes not sealed around pipes, insulation with gaping holes in it etc. Unfortunately, this is often only the start of the nightmare that follows from a rough job.

The next problem you will likely notice is poor performance. Rooms may be cold or not at an even temperature, or even too warm when you don't want them to be. Perhaps you will run out of hot water or have poor flow at the taps and showers.

Then you could get a real shock when it costs more to run than the gas system you just had removed, which saddens me as those poor consumers could then be put off heat pumps for life.

Finally, your heat pump may not last as long as you hoped, we say it should last around 15 years.

Thankfully, these problems will be easily avoided by choosing a reputable installer. Although it seems finding one is easier said than done. This is where we (and Heat Geek) come in.

I guess you're already wondering, how much does a proper job cost which doesn't come with all these problems? £7,000-£10,000 you hear on Google? In 2022? I don't think so. £10,000-£15,000 then? Maybe if your job is simple or your property is smaller than average or particularly well insulated. Or if you already have close to a "Heat pump ready" system At todays prices based on average UK housing stock which is notoriously poorly insulated, I say £15,000-£20,000 is more like it and you should get the £5000 BUS grant to come off this. This voucher is issued to the installer who applies for it on your behalf prior to your installation taking place. It should reduce the upfront cost to you, the user and not be refunded back later by any reputable installer participating in this scheme in the right spirit.

However, prices above this are not uncommon in larger than average and older properties, particularly solid brick wall Victorian houses which will need larger heat pumps, radiators and pipework if insulation isn't drastically improved (external wall insulation is a great solution, albeit an expensive one for these properties). As I have said in the past, do not fall for the misconception that you need to have an extremely well insulated house to have a heat pump. Insulation always helps, little is better than none and this will make the heat pump job cheaper. Remember, most research undertaken on heat pump pricing is based on quotes that actually went ahead, it doesn't include those that were deemed too expensive so the job wasn't done or they ended up getting a cheap job and regretting it later after running into the aforementioned problems.

So why do heat pumps cost so much? It's mostly down to the price of materials which can easily come to £10,000, maybe £15,000. Labour is less but still a significant cost. Installing heat pumps requires a lot of time, specialist knowledge and it's hard work! These things are heavy, not to mention if you need K3 (triple panel) radiators. Labour is usually £5000-£10,000, typically including a plumber, labourer or apprentice, electrician and commissioning engineer (This work combined may be completed by as little as two appropriately qualified persons).

There is a lot involved in designing a good heat pump system and too often, a lot of corners are cut. Bringing, yes you guessed it, a lot of problems. Often, the simpler the design, the better. We make sure to meet all Building Regulations, MCS standards and achieve appropriate permissions from your local planning authority and electricity district network operator (DNO). Not only this, but we make sure we design so the heat pump costs less to run than a gas boiler. If you go for the cheapest heat pump installed to the minimum standard, it could increase your energy bills and we will not offer that. We will offer the highest possible efficiency by lowering your flow temperature as much as we feasible can. It will always be highly efficient and come with a bespoke control strategy to suit you and your home.

We're talking 300-500% or even more in the best case scenarios with the most efficient heat pumps on the market with careful design and installation. That means for every 1kW of electricity used, your heat pump will produce 3-5kW of heat energy. Currently as I write this, electricity is around 3 times the price of gas. So as long as you achieve 300% plus efficiency, upgrading to a heat pump will reduce your heating bills. This figure is measured in what we call Seasonal Coefficient of Performance (SCOP). A SCOP of 3.5 means 350% efficiency. The price of gas is also rising faster than electricity and this trend is expected to continue due to natural gas being a finite resource and the electricity grid becoming more powered by renewables year on year. Long may this continue and it must if we are reach net zero which I deeply care about.

Here is a list of the most common issues I am seeing: Weather compensation turned off (fixed flow temperature) or left on factory settings.

Poor controls in general (on/off stats or weather compensation controllers which don’t parallel shift the curve during set back program or manual room temperature adjustment).

Little effort made to ensure the heat loss calculation is reasonably accurate resulting in grossly under or oversized heat pump or radiators which don't emit enough heat. Particular attention should be paid to designer/cast iron radiators as the manufacturer's often quote their outputs as higher than the industry standard flow temperatures for gas boilers. Your installer has to calculate the output of your emitters as your heat pump design flow temperature.

Undersized pipework (28mm isn’t a one size fits all).

Poor insulation on pipework (not high temperature, joints not sealed or not insulated through the wall or pipe clips underneath rather than on top of the insulation).

Undersized buffers or volumisers (when required). This could mean poor flow around your system and your heat pump failing to complete it's defrost procedure. Note buffers can be easily designed out and are mostly unnecessary if you are going for an open loop control strategy which is no TRV's or roomstats and running purely off weather compensation.

Pushfit plastic pipework used. (The fittings and pipework bore is narrower and absorbs oxygen at a greater rate). Just dreadful stuff in my opinion, if plastic pipe is to be used it should be MLCP which has an aluminium oxgyen barrier and uses press fittings.

Systems not flushed out properly or strainers not cleaned after installation (not sure it is even done at all on the 2-3 day installs).

Pump positioning wrong (pump away from buffer tanks or the hydraulic separation). No hydraulic separation when required (absolutely fine to pump right through a volumiser if your pipework is suitable and even preferable). Multiple pumps require hydraulic separation inbetween. Again, poor flow = poor efficiency, performance and reliability, it really can't be emphasised enough.

Underfloor heating manifold pumps and blending packs should be removed from the manifold(s) on a weather compensated system and pumped direct or electronically blended down if you have radiators as well. This also has the added benefit of a super efficient, variable floor temperature. Standard UFH pump blending packs are designed to bolt onto high temperature systems or they simply won't work properly.

Undersized expansion vessels.

No hot water circulation on pipe runs from the cylinder of over 10-12M (meaning the hot water takes a long time to reach your tap)

Undersized hot water cylinders. No one is happy when they run out of hot water, we design for 45 litres per person per day minimum. Thankfully this problem isn't the most common.

Immersion heater legionella program not set up (some cheaper heat pumps don’t integrate this).

Little or no effort gone into ensuring you have a solid, level base and sensible condensate removal.

Incorrect circuit breaker size.

Systems not balanced.

Installers not coming back to rectify any of the above. This is mostly associated with cheap installers who either don't care or they go bust from under estimating jobs.

Most of these problems are also commonly found on gas boiler systems, it's just with heat pumps, everything is more critical. You shouldn't get these problems if you find an installer that knows what they are doing and takes care in the design and installation.

If you have had these problems or spot them early, you can request your deposit back if the job hasn't started and it should always be insurance backed. Or if the job has begun or been completed, the workmanship warranty should also be insurance backed. Your installer should be your first port of call, you must give them a fair chance to rectify any issues if you wish to claim.

If these problems persist on your system, we can sort it.

Incase you’re thinking this all sounds too complicated and maybe better just wait for Hydrogen. I don’t think that’s coming any time soon. Most of Europe including much colder countries than ours are installing heat pumps at a greater rate than the UK and have done so for many years. The technology is not new but it is now more refined with the latest refrigerants and more efficient than ever. I firmly believe Heat Pumps are the solution for now and the future for affordable household heating bills and for our best bet to achieve net zero, much more so than Hydrogen for domestic heating which may never come to some areas. Remember To reach net zero by 2050, we need to replace millions of gas boilers with heat pumps. We just need to do it properly and that is what we’re all about.

We only cover a small area of North West England. To find a quality heat pump installer, I recommend you should check the Heat Geek Map where knowledge is tested to a far higher level than the MCS register which we are also on. https://www.heatgeek.com/find-a-heat-geek/ All Heat Geeks are trained in low temperature system design, a safe bet to avoid the biggest problems. We are listed on the map as Heat Geek Elite and proud. Here are some installations by fellow Heat Geeks which is the standard we work to.

Installed by SE Energy in Dorking.

Installed by Liam Barry of Custom Renewables of Oxfordshire

Installed by Shane Kosic of Kraken Plumbing & Heating Ltd of Bedford.

Installed by C Brookes Plumbing & Heating in Bristol.

Finally, I would like to say thank you for reading this and feel free to share it or to get in touch to discuss your existing or potential heat pump installation. If you’re within an hours drive of Southport, hopefully we can work together to achieve your low carbon goals.

Best wishes

Michael Sammon Eng Tech MCIPHE RP RHP Director